Dina dinten awal fabrikasi logam otomatis, nu boga usaha ilaharna resep meuli tabel plasma CNC primér atawa mesin motong waterjet mun kasarna motong logam kandel, sarta cutter plasma CNC rupa mun persis motong logam ipis. Kalayan kabutuhan pikeun kaamanan manufaktur sareng perlindungan lingkungan dina fabrikasi logam, YAG sareng CO2 mesin motong laser diwanohkeun dina pasaran, nu dibawa kualitas motong logam ka tingkat anyar. Sumawona, laser langkung ramah lingkungan sareng langkung aman tibatan plasma sareng waterjet, sareng henteu peryogi bahan-bahan. Sanajan kitu, duanana laser YAG jeung karbon dioksida boga watesan sorangan, kayaning waragad investasi tinggi, ketebalan motong kawates, komo speeds nu teu sakumaha alus sakumaha plasma. Dina waktu ieu, tipe anyar tina Sistim motong logam laser diluncurkeun, nyaéta serat laser. Ieu mangrupakeun mesin motong logam profésional. Naha éta kualitas, speed atanapi ketebalan, sakumaha kakuatan laser robah, éta geus ngahontal jangkung unprecedented. Fitur sareng kaunggulan tina precision tinggi, kualitas luhur, speed gancang, béaya rendah, betah pamakéan, sarta automation pinuh nyieun hiji unicorn di tube na lambar logam fabrikasi.

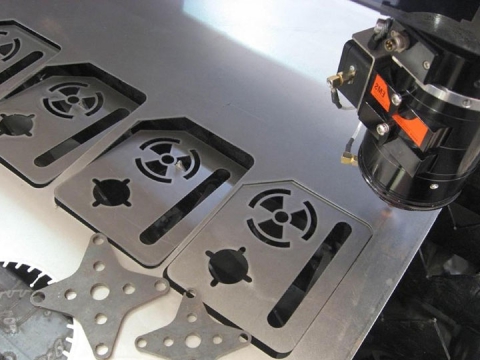

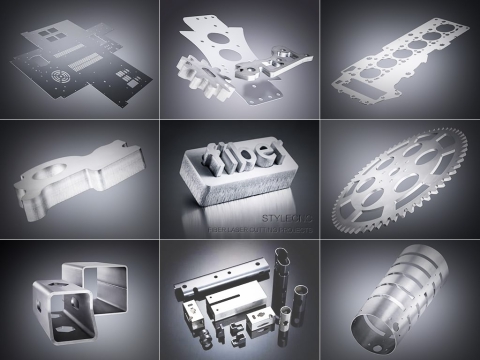

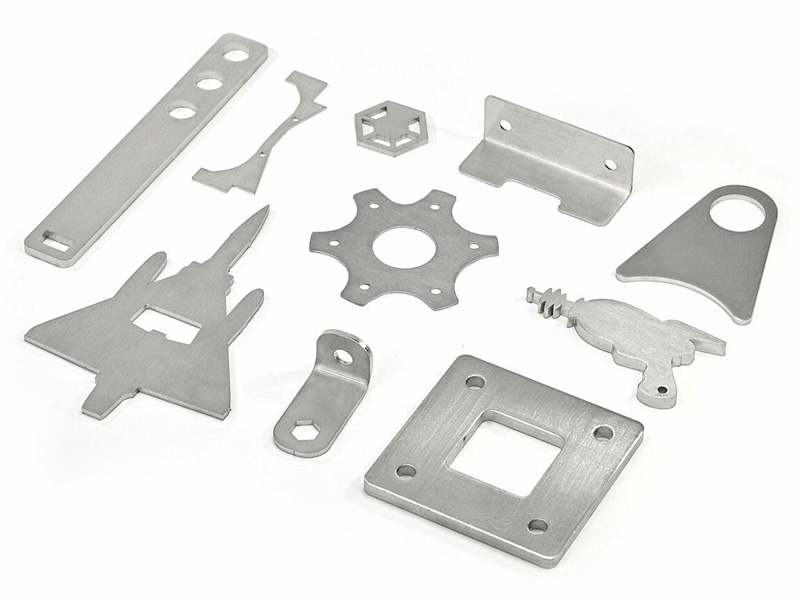

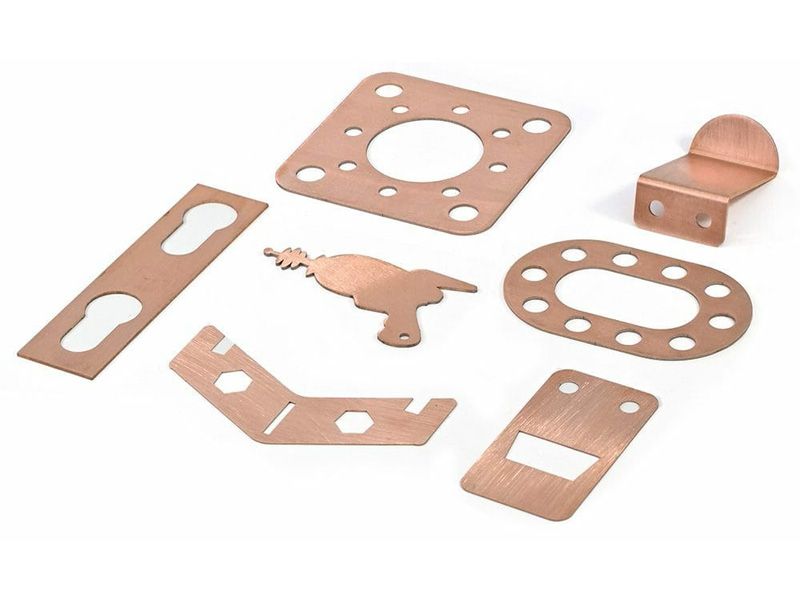

Serat laser cutter mangrupakeun tipe anyar-precision tinggi sistem motong logam anu ngagunakeun controller CNC ngajalankeun sirah laser pikeun motong logam jeung file perenah dirancang ngajadikeun otomatis fabrikasi logam dina usaha leutik jeung manufaktur industri. Ti 1mm stainless steel, nepi ka leuwih 100mm baja karbon, komo logam kacida reflective kayaning kuningan, tambaga, aluminium, emas, jeung pérak, éta bisa kalayan gampang motong ngaliwatan nyieun contours lemes kalayan gas kerja béda kaasup hawa, nitrogén jeung oksigén. Naha éta lambar logam, tabung atanapi profil khusus, mesin serat laser gaduh kamampuan pikeun motong bentuk anu tepat sareng bersih.

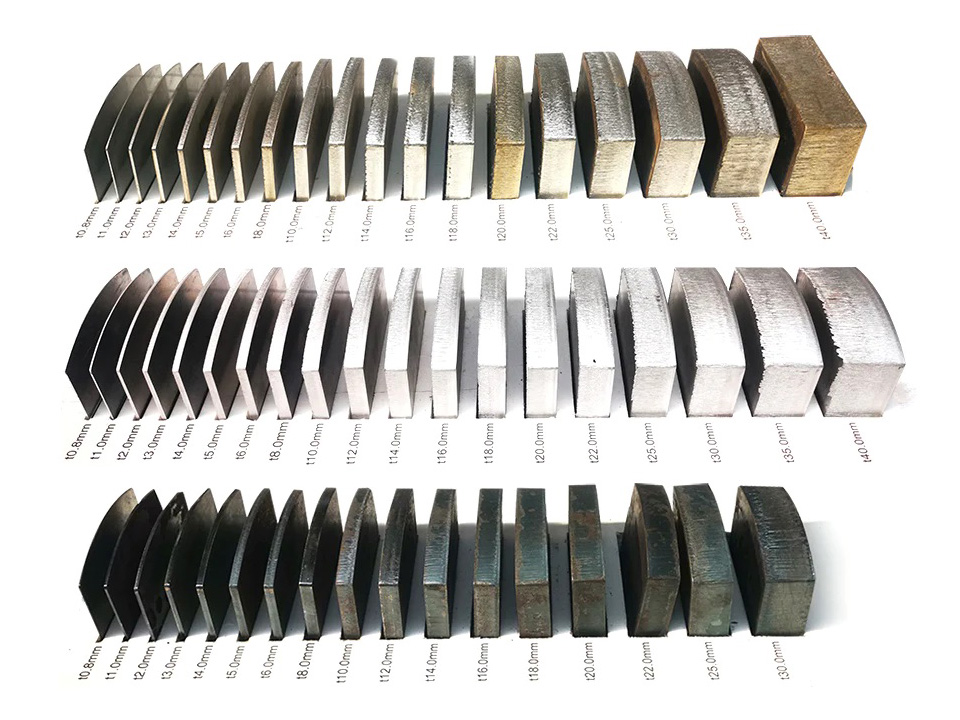

Nyanghareupan sapertos alat motong kuat, anjeun wondering sabaraha kandel logam eta bisa motong? Naon watesan laju motong? Kumaha rupa kakuatan laser nedunan dina motong ketebalan logam jeung speed? Ieu mangrupikeun pituduh praktis pikeun pamula sareng ahli, ngamungkinkeun urang ngadamel analisa lengkep tina sababaraha bahan logam, gas kerja, kakuatan laser, ketebalan motong sareng kecepatan.

Serat laser motong Karbon Steel Kandel & Speed & Power Bagan

Baja karbon nyaéta paduan beusi-karbon kalayan eusi karbon antara 0.02% sareng 2%.

Baja karbon anu tiasa dipotong laser serat kalebet baja karbon rendah (baja hampang), baja karbon sedeng (baja M2) sareng baja karbon tinggi (baja alat).

Serat laser cutters bisa kalayan gampang motong baja karbon mimitian ti 1mm nepi ka liwat 200mm dina speeds ti 0.12m / mnt ka 100m/ mnt, kalawan kakuatan pilihan mimitian ti 1000W sareng dugi ka 60000W, sareng pilihan gas anu tiasa dianggo kalebet hawa, oksigén, nitrogén sareng gas campuran.

Daya Lemah/Sedeng (1000W - 4000W) Parameter motong baja karbon

| material | gas | Ketebalan (mm) | Laju (m/mnt) | ||||

|---|---|---|---|---|---|---|---|

| 1000W | 1500W | 2000W | 3000W | 4000W | |||

| karbon Steel | hawa | 1 | 12.0-15.0 | 15.0-20.0 | 25.0-30.0 | 28.0-35.0 | 30.0-38.0 |

| 2 | 3.5-4.5 | 5.0-8.0 | 7.0-10.0 | 8.0-12.0 | 10.0-16.0 | ||

| 3 | 1.5-3.0 | 2.0-4.0 | 2.5-4.5 | 3.0-5.0 | |||

| 4 | 1.5-2.3 | 2.5-3.5 | |||||

| 5 | 1.0-2.2 | ||||||

| N₂ | 1 | 15.0-20.0 | 18.0-25.0 | 22.0-30.0 | 25.0-38.0 | 30.0-44.0 | |

| O₂ | 2 | 3.5-5.0 | 3.8-5.0 | 5.0-6.0 | 5.5-7.0 | 5.5-7.7 | |

| 3 | 2.5-3.5 | 2.8-3.8 | 3.5-4.3 | 3.6-5.0 | 3.7-5.5 | ||

| 4 | 2.0-3.3 | 2.3-3.5 | 2.8-4.0 | 3.0-4.5 | 3.5-4.6 | ||

| 5 | 1.4-2.0 | 1.6-2.5 | 2.5-3.0 | 2.5-3.3 | 2.5-4.0 | ||

| 6 | 1.2-1.6 | 1.4-1.8 | 2.2-2.5 | 2.3-2.8 | 2.5-3.5 | ||

| 8 | 0.8-1.1 | 0.9-1.3 | 1.3-1.8 | 1.8-2.2 | 2.0-2.8 | ||

| 10 | 0.6-0.9 | 0.8-1.2 | 1.2-1.5 | 1.2-1.6 | 1.2-2.2 | ||

| 12 | 0.4-0.7 | 0.7-1.0 | 0.8-1.0 | 1.0-1.3 | 1.0-1.7 | ||

| 16 | 0.5-0.7 | 0.6-0.8 | 0.6-0.9 | 0.7-1.0 | |||

| 20 | 0.5-0.8 | 0.6-0.9 | |||||

| 22 | 0.5-0.8 | ||||||

Kakuatan luhur (6000W - 30000W) Parameter motong baja karbon

| material | gas | Ketebalan (mm) | Laju (m/mnt) | |||||

|---|---|---|---|---|---|---|---|---|

| 6000W | 8000W | 12000W | 15000W | 20000W | 30000W | |||

| karbon Steel | hawa | 1 | 35.0-42.0 | 38.0-45.0 | 45.0-60.0 | 50.0-70.0 | 60.0-100.0 | 70.0-100.0 |

| 2 | 20.0-28.0 | 25.0-35.0 | 35.0-48.0 | 45.0-52.0 | 50.0-70.0 | 60.0-73.0 | ||

| 3 | 8.0-15.0 | 18.0-25.0 | 25.0-38.0 | 30.0-40.0 | 45.0-52.0 | 50.0-57.0 | ||

| 4 | 7.0-12.0 | 15.0-18.0 | 18.0-26.0 | 25.0-29.0 | 30.0-40.0 | 35.0-43.0 | ||

| 5 | 5.0-9.0 | 10.0-12.0 | 12.0-20.0 | 18.0-23.0 | 23.0-28.0 | 25.0-30.0 | ||

| 6 | 3.0-6.0 | 8.0-9.0 | 9.0-13.0 | 13.0-19.0 | 18.0-23.0 | 19.0-26.0 | ||

| 8 | 5.0-5.5 | 6.0-8.0 | 8.0-12.0 | 12.0-16.0 | 14.0-18.0 | |||

| 10 | 5-6.5 | 6.0-8.5 | 11.0-13.0 | 12.0-14.0 | ||||

| 12 | 4.0-4.6 | 5.0-6.0 | 7.0-10.0 | 10.0-12.0 | ||||

| 16 | 4.5-5.5 | 6.5-7.0 | 8.0-8.5 | |||||

| 20 | 2.7-3.2 | 4.5-5.5 | ||||||

| 22 | 2.9-3.5 | |||||||

| 25 | 2.0-3.2 | |||||||

| N₂ | 1 | 35.0-48.0 | 60.0-70.0 | 66.0-80.0 | 70.0-90.0 | 80.0-95.0 | 95.0-100.0 | |

| O₂ | 2 | 6.0-8.25 | 6.8-7.2 | 7.2-7.8 | 7.5-8.2 | 7.8-8.5 | 8.0-10.0 | |

| 3 | 4.0-5.5 | 4.8-5.5 | 5.2-5.8 | 5.5-6.0 | 5.8-6.3 | 6.0-7.0 | ||

| 4 | 3.5-5.0 | 3.8-4.3 | 4.2-4.6 | 4.5-5.2 | 4.8-5.5 | 5.0-6.5 | ||

| 5 | 3.0-4.2 | 3.3-4.3 | 3.8-4.7 | 4.0-5.0 | 4.3-4.8 | 4.5-5.0 | ||

| 6 | 2.6-3.5 | 3.0-3.4 | 3.5-4.0 | 3.8-4.3 | 4.0-4.5 | 4.2-4.8 | ||

| 8 | 2.0-2.8 | 2.3-3.0 | 2.6-3.3 | 2.8-3.5 | 3.0-3.6 | 3.5-4.0 | ||

| 10 | 1.8-2.3 | 2.0-2.5 | 2.5-3.0 | 2.6-3.0 | 2.8-3.2 | 3.0-3.5 | ||

| 12 | 1.6-2.1 | 1.7-2.2 | 2.0-2.3 | 2.5-3.0 | 2.7-3.2 | 2.8-3.4 | ||

| 16 | 0.7-1.0 | 1.2-1.4 | 1.4-1.6 | 1.7-2.0 | 1.9-2.3 | 2.0-2.5 | ||

| 20 | 0.5-0.9 | 1.0-1.1 | 1.2-1.5 (2.1) | 1.3-1.6 | 1.5-1.8 | 1.6-2.0 | ||

| 22 | 0.5-0.7 | 0.9-1.0 | 0.9-1.2 | 1.1-1.3 | 1.3-1.6 | 1.5-1.8 | ||

| 25 | 0.4-0.6 | 0.6-0.7 | 0.6-0.9 | 0.9-1.2 | 1.0-1.4 | 1.3-1.5 | ||

| 30 | 0.3-0.6 | 0.5-0.8 | 0.6-0.8 | 0.8-1.2 | 1.2-1.4 | |||

| 40 | 0.25-0.33 | 0.4-0.7 | 0.7-0.9 | 0.9-1.1 | ||||

| 50 | 0.18-0.2 | 0.2-0.25 | 0.3-0.5 | 0.6-0.8 | ||||

| 60 | 0.18-0.2 | 0.2-0.25 | 0.22-0.28 | |||||

| 70 | 0.18-0.2 | 0.19-0.22 | ||||||

| 80 | 0.12-0.15 | |||||||

Kakuatan Ekstra Luhur (40000W) Parameter motong baja karbon

| material | Ketebalan (mm) | Laju (m/mnt) | Daya (watt) | Gas Gawé |

|---|---|---|---|---|

| karbon Steel | 5 | 28.0-32.0 | 40000 | N₂ / hawa |

| 6 | 25.0-28.0 | |||

| 8 | 22.0-24.0 | |||

| 10 | 16.0-20.0 | |||

| 12 | 14.0-17.0 | |||

| 14 | 11.0-13.0 | |||

| 16 | 8.0-9.5 | |||

| 18 | 8.0-8.5 | |||

| 20 | 7.0-8.0 | |||

| 25 | 5.0-5.5 | |||

| 30 | 3.0-4.0 | |||

| 40 | 1.5-2.0 | |||

| 50 | 0.7-1.0 | |||

| 10 | 2.0-2.3 | 6000 | O₂ (Fokus Positip) | |

| 12 | 1.8-2.0 | 7,500 | ||

| 14 | 1.6-1.8 | 8,500 | ||

| 16 | 1.6-1.8 | 9,500 | ||

| 20 | 1.5-1.6 | 12000 | ||

| 22 | 1.4-1.5 | 18000 | ||

| 25 | 1.2-1.4 | 18000 | ||

| 30 | 1.2-1.3 | 18000 | ||

| 40 | 0.9-1.1 | 26000 | ||

| 40 (Non-Q235) | 0.3-0.6 | 20000 | ||

| 50 (Non-Q235) | 0.3-0.5 | 25000 | ||

| 50 | 0.8-1.0 | 40000 | ||

| 60 | 0.6-0.9 | |||

| 70 | 0.5-0.7 | |||

| 80 | 0.4-0.6 | |||

| 90 | 0.3-0.4 | |||

| 100 | 0.2-0.3 | |||

| 12 | 3.2-3.5 | 20000 | O₂ (Fokus Negatip) | |

| 14 | 3.0-3.2 | |||

| 16 | 3.0-3.1 | |||

| 20 | 2.8-3.2 | |||

| 25 | 2.4-2.8 | 40000 | ||

| 30 | 2.4-2.6 | |||

| 35 | 2.3-2.6 | |||

| 40 | 2.0-2.3 | |||

| 50 | 1.2-1.6 | |||

| 60 | 1.0-1.3 | |||

| 70 | 0.6-0.8 |

Kakuatan Ultra-Luhur (60000W) Parameter motong baja karbon

| material | Ketebalan (mm) | Laju (m/mnt) | Daya (watt) | Gas Gawé |

|---|---|---|---|---|

| karbon Steel | 16 | 13.0-14.0 | 60000 | Gas Campuran - (N₂&O₂)/hawa |

| 18 | 11.0-12.0 | |||

| 20 | 9.0-10.0 | |||

| 25 | 6.5-7.5 | |||

| 30 | 4.5-5.5 | |||

| 35 | 3.5-4.4 | |||

| 40 | 2.8-3.4 | |||

| 45 | 2.0-2.5 | |||

| 50 | 1.5-2.0 | |||

| 60 | 1.0-1.4 | |||

| 16 | 1.6-1.8 | 12000 | O₂ (Fokus Positip) | |

| 18 | 1.6-1.7 | |||

| 20 | 1.5-1.6 | |||

| 25 | 1.2-1.4 | 20000 | ||

| 30 | 1.2-1.3 | |||

| 35 | 1.1-1.2 | |||

| 40 | 0.9-1.1 | 25000 | ||

| 45 | 0.8-1.0 | |||

| 50 | 0.75-0.9 | 30000 | ||

| 60 | 0.7-0.8 | 50000 | ||

| 70 | 0.7-0.8 | 60000 | ||

| 80 | 0.6-0.7 | |||

| 100 | 0.5-0.6 | |||

| 160 | 0.15-0.25 | |||

| 200 | 0.15-0.2 | |||

| 20 | 2.4-3.0 | 15000 | O₂ (Fokus Negatip) | |

| 25 | 2.2-2.6 | 30000 | ||

| 30 | 2.0-2.4 | |||

| 35 | 2.0-2.2 | 35000 | ||

| 40 | 1.6-2.0 | |||

| 45 | 1.4-1.8 | 40000 | ||

| 50 | 1.2-1.6 | |||

| 60 | 1.0-1.3 | 60000 | ||

| 70 | 1.0-1.2 | |||

| 80 | 0.8-1.0 | |||

| 100 | 0.5-0.65 |

Serat laser motong ketebalan stainless steel & speed & Bagan kakuatan

Baja tahan karat ngarujuk kana baja paduan anu pasip, tahan korosi, henteu karat, sareng ngandung kromium anu luhur (biasana 12%~30%) dina atmosfir jeung média corrosive kayaning asam, alkalis, jeung uyah, nu ngandung nikel, molybdenum, vanadium, mangan, tungsten jeung elemen séjén, ogé katelah baja tahan asam, beusi bodas, beusi tambaga cai.

The A.STM sasmita jeung model tina stainless steel yén serat laser tiasa motong kalebet 201, 202, 205, 301, 302, 302B, 302Cu, 303, 304, 304L, 304N, 305, 308, 309, 310, 314, 316L, 316, 316L, 317 317L, 321, 329, 330, 347, 384, 403, 405, 409, 410, 414, 416, 420, 422, 429, 430, 430F, 431, 434, 436 439 440B, 440C ), 44, 0, 440, 444, 446L sareng 501.

Serat laser mesin motong mampuh motong stainless steel ipis 1 milimeter sarta sa kandel 150 milimeter dina speeds sahandapeun 0.05 méter per menit sarta saluhur 100 méter per menit, kalawan kakuatan laser mimitian ti 1000W ka 60000W, sareng gas kerja opsional N₂ sareng Udara.

Daya Lemah/Sedeng (1000W - 4000W) Parameter motong stainless steel

| material | gas | Ketebalan (mm) | Laju (m/mnt) | ||||

|---|---|---|---|---|---|---|---|

| 1000W | 1500W | 2000W | 3000W | 4000W | |||

| Beusi sténless | hawa | 1 | 15.0-25.0 | 18.0-30.0 | 20.0-35.0 | 32.0-40.0 | 35.0-50.0 |

| 2 | 4.0-7.0 | 8.0-12.0 | 10.0-15.0 | 14.0-18.0 | 16.0-23.0 | ||

| 3 | 2.5-3.5 | 3.0-4.0 | 5.0-7.0 | 8.0-12.0 | 8.0-14.0 | ||

| 4 | 0.6-1.0 | 2.0-3.0 | 3.5-4.5 | 5.5-8.0 | 6.0-10.0 | ||

| 5 | 0.5-0.8 | 1.2-1.8 | 1.8-2.5 | 3.5-5.0 | 4.5-6.0 | ||

| 6 | 0.5-0.8 | 0.7-0.8 | 2.5-3.0 | 2.8-4.8 | |||

| 8 | 0.5 | 1.2-1.5 | 1.8-3.0 | ||||

| 10 | 0.8-1.2 | 0.85-1.8 | |||||

| 12 | 0.65-1.0 | ||||||

| N₂ | 1 | 16.5-22.0 | 20.0-26.0 | 27.5-33.0 | 31.0-38.5 | 33.0-45.0 | |

| 2 | 4.5-6.1 | 7.0-10.0 | 9.0-11.0 | 12.0-16.5 | 15.0-20.0 | ||

| 3 | 2.0-3.1 | 4.5-5.5 | 5.0-6.5 | 7.0-10.0 | 7.5-12.0 | ||

| 4 | 1.0-1.6 | 2.0-2.5 | 2.2-2.8 | 5.0-7.2 | 5.5-9.0 | ||

| 5 | 0.4-0.7 | 1.5-2.0 | 1.5-2.0 | 1.8-2.4 | 4.0-5.5 | ||

| 6 | 0.6-0.9 | 0.7-1.3 | 1.0-1.6 | 2.6-4.5 | |||

| 8 | 0.3-0.6 | 1.2-2.0 | 1.6-2.8 | ||||

| 10 | 0.7-1.0 | 0.7-1.6 | |||||

| 12 | 0.5-0.9 | ||||||

Kakuatan luhur (6000W - 30000W) Parameter motong stainless steel

| material | gas | Ketebalan (mm) | Laju (m/mnt) | |||||

|---|---|---|---|---|---|---|---|---|

| 6000W | 8000W | 12000W | 15000W | 20000W | 30000W | |||

| Beusi sténless | hawa | 1 | 55.0-70.0 | 65.0-75.0 | 70.0-85.0 | 80.0-95.0 | 83.0-100.0 | 85.0-100.0 |

| 2 | 32.0-45.0 | 40.0-50.0 | 45.0-55.0 | 48.0-55.0 | 55.0-70.0 | 65.0-80.0 | ||

| 3 | 20.0-28.0 | 27.0-33.0 | 30.0-38.0 | 35.0-40.0 | 45.0-52.0 | 55.0-60.0 | ||

| 4 | 13.0-18.0 | 15.0-20.0 | 25.0-30.0 | 25.0-29.0 | 30.0-40.0 | 38.0-45.0 | ||

| 5 | 10.0-15.0 | 12.0-16.0 | 16.0-19.0 | 18.0-23.0 | 23.0-28.0 | 27.0-33.0 | ||

| 6 | 7.0-10.0 | 9.0-11.0 | 13.0-17.0 | 14.0-19.0 | 18.0-23.0 | 24.0-28.0 | ||

| 8 | 4.5-6.0 | 5.5-6.0 | 9.0-11.0 | 8.0-12.0 | 14.0-16.0 | 20.0-24.0 | ||

| 10 | 2.0-3.0 | 4.0-4.5 | 6.5-8.0 | 6.8-8.5 | 9.0-12.0 | 15.0-20.0 | ||

| 12 | 1.4-1.8 | 2.5-3.5 | 5.5-6.0 | 5.5-6.5 | 8.0-10.0 | 12.5-15.0 | ||

| 16 | 0.8-1.0 | 1.3-2.0 | 2.2-2.8 | 4.5-5.5 | 5.5-6.5 | 8.0-9.0 | ||

| 20 | 0.5 | 0.7-1.0 | 1.5-2.0 | 1.9-2.1 | 2.7-3.2 | 4.5-5.5 | ||

| 25 | 0.5-0.8 | 0.8-1.2 | 1.2-1.4 | 1.8-2.5 | 2.5-3.0 | |||

| 30 | 0.25-0.4 | 0.5-0.8 | 0.8-1.0 | 1.4-1.6 | 1.5-2.2 | |||

| 40 | 0.4-0.5 | 0.5-0.8 | 0.8-1.0 | |||||

| 50 | 0.17-0.3 | 0..3-0.4 | 0.3-0.45 | |||||

| 60 | 0.14-0.18 | 0.16-0.2 | ||||||

| 70 | 0.1-0.13 | 0.1-0.15 | ||||||

| 80 | 0.05 | |||||||

| N₂ | 1 | 50.0-65.0 | 63.0-66.0 | 70.0-80.0 | 75.0-90.0 | 80.0-100.0 | 82.0-100.0 | |

| 2 | 30.0-40.0 | 40.0-44.0 | 44.0-48.0 | 46.0-50.0 | 50.0-60.0 | 63.0-75.0 | ||

| 3 | 18.0-25.0 | 25.0-28.0 | 28.0-35.0 | 30.0-38.0 | 35.0-45.0 | 52.0-58.0 | ||

| 4 | 10.0-15.5 | 15.0-18.0 | 20.0-26.0 | 22.0-28.0 | 30.0-32.0 | 35.0-43.0 | ||

| 5 | 8.0-13.5 | 12.0-14.0 | 15.0-20.0 | 16.0-22.0 | 24.0-28.0 | 25.0-30.0 | ||

| 6 | 6.0-9.0 | 9.0-9.5 | 11.0-13.0 | 12.0-15.0 | 20.0-25.0 | 22.0-25.0 | ||

| 8 | 4.0-5.5 | 5.0-5.3 | 7.0-7.5 | 7.5-8.5 | 14.0-17.0 | 18.0-22.0 | ||

| 10 | 1.8-2.8 | 3.8-4.0 | 5.0-5.5 | 5.5-6.5 | 10.0-13.0 | 14.0-18.0 | ||

| 12 | 1.2-1.6 | 2.5-2.7 | 3.0-3.5 | 3.3-4.0 | 9.0-10.0 | 12.0-14.0 | ||

| 14 | 0.8-1.2 | 1.8-1.9 | 2.3-2.8 | 2.5-3.0 | 7.0-8.5 | 8.0-10.0 | ||

| 16 | 0.6-0.9 | 1.3-1.5 | 2.1-2.5 | 2.3-2.8 | 5.0-6.0 | 7.0-8.0 | ||

| 20 | 0.7-0.8 | 1.4-1.7 | 1.5-1.9 | 2.5-3.0 | 4.0-5.0 | |||

| 25 | 0.5-0.6 | 0.7-1.0 | 0.9-1.2 | 1.4-1.8 | 2.0-2.5 | |||

| 30 | 0.5-0.7 | 0.6-0.8 | 0.9-1.2 | 1.2-2.0 | ||||

| 35 | 0.4-0.5 | 0.5 | 0.55-0.8 | 0.7-1.0 | ||||

| 40 | 0.3 | 0.4 | 0.4-0.5 | 0.6-0.8 | ||||

| 50 | 0.2 | 0.25 | 0.3-0.35 | 0.3-0.4 | ||||

| 60 | 0.15 | 0.15-0.2 | 0.15-0.25 | |||||

| 70 | 0.1-0.13 | 0.12-0.15 | ||||||

| 80 | 0.06-0.08 | 0.08-0.1 | ||||||

| 90 | 0.05-0.06 | 0.5-0.08 | ||||||

| 100 | 0.03-0.04 | 0.04-0.05 | ||||||

Kakuatan Ekstra Luhur (40000W) Parameter motong stainless steel

| material | Ketebalan (mm) | Laju (m/mnt) | Daya (watt) | Gas Gawé |

|---|---|---|---|---|

| Beusi sténless | 5 | 25.0-30.0 | 40000 | N₂ |

| 6 | 22.0-25.0 | |||

| 8 | 20.0-23.0 | |||

| 10 | 16.0-21.0 | |||

| 12 | 12.0-14.0 | |||

| 14 | 10.0-12.0 | |||

| 16 | 9.0-11.0 | |||

| 18 | 8.0-9.5 | |||

| 20 | 7.0-8.5 | |||

| 25 | 4.5-5.5 | |||

| 30 | 3.0-4.0 | |||

| 40 | 1.5-2.0 | |||

| 50 | 0.5-0.8 | |||

| 60 | 0.4-0.6 | |||

| 70 | 0.2-0.3 | |||

| 80 | 0.2-0.25 | |||

| 90 | 0.14-0.18 | |||

| 100 | 0.08-0.12 | |||

| 5 | 30.0-34.0 | 40000 | hawa | |

| 6 | 25.0-30.0 | |||

| 8 | 22.0-25.0 | |||

| 10 | 17.0-23.0 | |||

| 12 | 13.0-16.0 | |||

| 14 | 12.0-14.0 | |||

| 16 | 9.0-11.5 | |||

| 18 | 8.0-10.0 | |||

| 20 | 7.0-9.0 | |||

| 25 | 5.0-5.5 | |||

| 30 | 3.5-4.5 | |||

| 40 | 1.7-2.2 | |||

| 50 | 0.7-1.0 | |||

| 60 | 0.4-0.6 | |||

| 70 | 0.3-0.4 | |||

| 80 | 0.25-0.3 | |||

| 90 | 0.2-0.25 | |||

| 100 | 0.15-0.2 |

Kakuatan Ultra-Luhur (60000W) Parameter motong stainless steel

| material | Ketebalan (mm) | Laju (m/mnt) | Daya (watt) | Gas Gawé |

|---|---|---|---|---|

| Beusi sténless | 16 | 13.0-14.0 | 60000 | N₂ |

| 18 | 11.0-12.0 | |||

| 20 | 9.0-10.0 | |||

| 25 | 6.5-7.5 | |||

| 30 | 5.0-6.0 | |||

| 35 | 3.5-4.5 | |||

| 40 | 3.0-3.5 | |||

| 50 | 1.8-2.2 | |||

| 60 | 1.3-1.6 | |||

| 70 | 1.0-1.2 | |||

| 80 | 0.6-0.8 | |||

| 90 | 0.4-0.6 | |||

| 90 (Modulasi) | 0.2-0.25 | |||

| 100 | 0.3-0.5 | |||

| 100 (Modulasi) | 0.15-0.2 | |||

| 120 | 0.1-0.15 | |||

| 16 | 13-14.5 | 60000 | hawa | |

| 18 | 11-12.5 | |||

| 20 | 9-10.5 | |||

| 25 | 7.0-7.8 | |||

| 30 | 5.0-6.0 | |||

| 35 | 4.0-4.5 | |||

| 40 | 3.2-4.0 | |||

| 50 | 3.0-3.5 | |||

| 60 | 1.8-2.2 | |||

| 70 | 1.0-1.2 | |||

| 80 | 0.7-0.8 | |||

| 90 | 0.5-0.6 | |||

| 100 | 0.4-0.5 | |||

| 120 | 0.25-0.35 | |||

| 150 | 0.15-0.2 | |||

| 200 (Modulasi) | 0.05-0.1 |

Serat laser motong ketebalan aluminium & speed & Power Bagan

Aluminium mangrupa logam lampu pérak-bodas paling loba pisan, nu lemes jeung pangleuleusna.

Lasers bisa kalayan gampang motong ngaliwatan foils, cadar, strips, tabung, rod na propil dijieunna tina aluminium sarta alloy.

Sistim motong laser serat anu idéal pikeun motong aluminium digulung, tuang aluminium, alloy aluminium murni, alloy aluminium kalawan tambaga, mangan, silikon, magnésium jeung séng nepi ka 100mm kandel dina laju maksimum 70m/ mnt, kalawan pilihan kakuatan laser ti 1000W ka 40000W jeung gas gawé N₂.

Daya Lemah/Sedeng (1000W - 4000W) Paraméter motong aluminium

| material | gas | Ketebalan (mm) | Laju (m/mnt) | ||||

|---|---|---|---|---|---|---|---|

| 1000W | 1500W | 2000W | 3000W | 4000W | |||

| aluminium | N₂ | 1 | 10.0-13.0 | 15.0-27.5 | 22.0-31.0 | 25.0-30.0 | 28.0-32.0 |

| 2 | 2.0-4.5 | 7.0-8.6 | 10.0-13.2 | 15.0-18.0 | 16.0-20.0 | ||

| 3 | 0.6-1.3 | 2.5-4.0 | 5.0-6.6 | 7.0-8.0 | 10.0-12.0 | ||

| 4 | 1.0-1.6 | 1.5-2.2 | 5.0-6.0 | 6.0-7.0 | |||

| 5 | 0.6-0.9 | 1.0-1.3 | 2.5-3.0 | 4.0-5.0 | |||

| 6 | 0.6-0.9 | 1.5-2.0 | 2.5-3.0 | ||||

| 8 | 0.4-0.7 | 0.5-0.8 | 1.0-1.3 | ||||

| 10 | 0.3-0.4 | 0.8-1.0 | |||||

| 12 | 0.6-0.8 | ||||||

| 14 | 0.3-0.5 | ||||||

Kakuatan luhur (6000W - 30000W) Paraméter motong aluminium

| material | gas | Ketebalan (mm) | Laju (m/mnt) | |||||

|---|---|---|---|---|---|---|---|---|

| 6000W | 8000W | 12000W | 15000W | 20000W | 30000W | |||

| aluminium | N₂ | 1 | 35.0-45.0 | 40.0-50.0 | 45.0-55.0 | 50.0-60.0 | 55.0-65.0 | 60.0-70.0 |

| 2 | 20.0-25.0 | 25.0-30.0 | 30.0-35.0 | 35.0-38.0 | 40.0-45.0 | 45.0-50.0 | ||

| 3 | 14.0-16.0 | 15.0-23.0 | 20.0-25.0 | 25.0-30.0 | 30.0-35.0 | 38.0-45.0 | ||

| 4 | 8.0-10.0 | 12.0-16.0 | 18.0-20.0 | 20.0-23.0 | 25.0-30.0 | 28.0-35.0 | ||

| 5 | 5.0-7.0 | 7.0-10 | 14.0-16.0 | 15.0-18.0 | 18.0-20.0 | 20.0-25.0 | ||

| 6 | 3.5-4.0 | 5.0-7.0 | 10.0-12.0 | 12.0-14.0 | 16.0-18.0 | 18.0-22.0 | ||

| 8 | 1.5-2.0 | 2.5-4.0 | 6.0-8.0 | 8.0-10.0 | 10.0-13.0 | 14.0-18.0 | ||

| 10 | 1.0-1.2 | 2.0-2.5 | 4.0-6.0 | 5.0-7.0 | 9.5-10.0 | 12.0-15.0 | ||

| 12 | 0.6-0.7 | 1.6-2.0 | 2.0-3.0 | 2.5-3.5 | 5.0-6.0 | 10.0-12.0 | ||

| 14 | 0.4-0.6 | 0.8-1.2 | 1.5-2.5 | 2.0-3.0 | 4.5-5.0 | 8.0-10.0 | ||

| 16 | 0.3-0.4 | 0.8-1.0 | 1.3-2.0 | 1.5-2.5 | 3.0-4.0 | 6.0-8.0 | ||

| 20 | 0.5-0.7 | 0.8-1.2 | 0.8-1.2 | 1.6-2.0 | 2.0-3.0 | |||

| 25 | 0.4-0.5 | 0.5-0.7 | 0.5-0.7 | 1.0-1.2 | 1.5-2.0 | |||

| 30 | 0.4-0.5 | 0.45-0.6 | 0.8-1.0 | 1.0-1.2 | ||||

| 35 | 0.3-0.35 | 0.45-0.55 | 0.7-0.9 | 0.8-1.0 | ||||

| 40 | 0.25-0.3 | 0.28-0.33 | 0.4-0.7 | 0.5-0.8 | ||||

| 50 | 0.15-0.2 | 0.2-0.25 | 0.3-0.5 | 0.4-0.6 | ||||

| 60 | 0.2 | 0.2-0.3 | 0.25-0.35 | |||||

| 70 | 0.08-0.13 | 0.12-0.15 | ||||||

| 80 | 0.08-0.1 | |||||||

Kakuatan Ekstra Luhur (40000W) Paraméter motong aluminium

| material | Ketebalan (mm) | Laju (m/mnt) | Daya (watt) | Gas Gawé |

|---|---|---|---|---|

| aluminium | 5 | 25.0-30.0 | 40000 | N₂ |

| 6 | 20.0-25.0 | |||

| 8 | 18.0-22.0 | |||

| 10 | 14.0-17.0 | |||

| 12 | 11.0-13.0 | |||

| 14 | 9.0-11.0 | |||

| 16 | 7.0-9.0 | |||

| 18 | 5.0-7.0 | |||

| 20 | 4.0-5.0 | |||

| 25 | 3.0-3.5 | |||

| 30 | 2.0-3.0 | |||

| 40 | 1.0-1.5 | |||

| 50 | 0.4-0.6 | |||

| 60 | 0.2-0.3 | |||

| 70 | 0.2-0.25 | |||

| 80 | 0.15-0.2 | |||

| 90 | 0.12-0.15 | |||

| 100 | 0.08-0.1 |

Serat laser motong Kuningan & Kandel tambaga & Speed & Power Bagan

Tambaga mangrupakeun logam lemes sareng ductile kalawan konduktivitas listrik alus teuing, konduktivitas termal, ductility, sarta lalawanan korosi. Kuningan mangrupikeun paduan tambaga sareng séng kalayan sipat mékanis anu luhur sareng résistansi ngagem.

Lasers bisa kalayan gampang motong ngaliwatan kuningan pikeun nyieun instrumen precision, bagian kapal, komponén éléktronik, cangkang gun, alat musik, hiasan, koin jeung molds.

Salian tambaga biasa sareng kuningan, serat laser ogé gaduh kamampuan pikeun motong parunggu aluminium, parunggu mangan, kuningan aluminium, logam gun (perunggu timah-séng), tambaga bodas sareng alloy nikel-tembaga (Monel) kalayan ketebalan tina 1mm ka 80mm dina speeds ti 0.4m / mnt ka 65m / mnt, kalawan kakuatan laser sakumaha low salaku 1000W jeung saluhureuna 40000W, ngagunakeun nitrogén pikeun motong kuningan jeung oksigén pikeun motong tambaga.

Daya Lemah/Sedeng (1000W - 4000W) Parameter motong Kuningan

| material | gas | Ketebalan (mm) | Laju (m/mnt) | ||||

|---|---|---|---|---|---|---|---|

| 1000W | 1500W | 2000W | 3000W | 4000W | |||

| kuningan | N₂ | 1 | 14.0-20.0 | 15.0-22.0 | 20.0-27.0 | 20.0-28.0 | 25.0-30.0 |

| 2 | 3.0-4.5 | 4.0-7.2 | 7.7-8.8 | 7.0-13.2 | 12.0-15.0 | ||

| 3 | 1.0-1.2 | 1.1-1.5 | 3.0-4.5 | 5.0-7.2 | 5.5-7.7 | ||

| 4 | 1.0-1.2 | 1.3-1.8 | 2.5-3.0 | 3.5-5.5 | |||

| 5 | 0.6-0.9 | 0.8-0.9 | 1.6-2.0 | 2.0-3.5 | |||

| 6 | 0.4-0.6 | 0.8-1.2 | 1.4-2.2 | ||||

| 8 | 0.3-0.4 | 0.8-1.0 | |||||

| 10 | 0.4-0.6 | ||||||

Kakuatan luhur (6000W - 30000W) Parameter motong Kuningan

| material | gas | Ketebalan (mm) | Laju (m/mnt) | |||||

|---|---|---|---|---|---|---|---|---|

| 6000W | 8000W | 12000W | 15000W | 20000W | 30000W | |||

| kuningan | N₂ | 1 | 30.0-40.0 | 35.0-45.0 | 38.0-50.0 | 40.0-55.0 | 45.0-60.0 | 55.0-65.0 |

| 2 | 15.0-18.0 | 25.0-27.0 | 30.0-35.0 | 32.0-37.0 | 35.0-40.0 | 38.0-45.0 | ||

| 3 | 12.0-14.0 | 15.0-18.0 | 18.0-22.0 | 20.0-24.0 | 25.0-28.0 | 28.0-33.0 | ||

| 4 | 8.0-10.0 | 10.0-12.0 | 15.0-18.0 | 16.0-19.0 | 19.0-22.0 | 22.0-26.0 | ||

| 5 | 5.0-5.5 | 7.0-9.0 | 12.0-15.0 | 13.0-16.0 | 17.0-19.0 | 18.5-22.0 | ||

| 6 | 3.2-3.8 | 6.0-6.5 | 7.0-10.0 | 9.0-11.0 | 12.0-15.0 | 15.0-18.0 | ||

| 8 | 1.5-1.8 | 2.5-3.0 | 5.5-6.5 | 6.0-8.0 | 8.0-10.0 | 10.0-15.0 | ||

| 10 | 0.8-1.0 | 1.0-1.5 | 3.5-4.7 | 5.0-6.0 | 7.0-8.0 | 8.0-10.0 | ||

| 12 | 0.6-0.7 | 0.8-1.2 | 1.8-2.0 | 2.0-2.2 | 2.5-3.5 | 5.0-8.0 | ||

| 15 | 0.6-0.7 | 1.0-1.2 | 1.3-1.4 | 1.8-2.0 | 2.5-4.5 | |||

| 18 | 0.5-0.7 | 0.8-1.2 | 0.8-1.3 | 1.3-1.8 | ||||

| 20 | 0.3-0.5 | 0.6-0.7 | 0.8-1.0 | 1.0-1.2 | ||||

| 25 | 0.4-0.6 | 0.7-0.9 | 0.8-1.0 | |||||

| 30 | 0.3-0.5 | 0.5-0.7 | 0.6-0.8 | |||||

| 40 | 0.4-0.5 | 0.5-0.65 | ||||||

| 50 | 0.4-0.5 | |||||||

Kakuatan Ekstra Luhur (40000W) Parameter motong Kuningan & Tambaga

| material | Ketebalan (mm) | Laju (m/mnt) | Daya (watt) | Gas Gawé |

|---|---|---|---|---|

| kuningan | 5 | 25.0-30.0 | 40000 | N₂ |

| 6 | 20.0-25.0 | |||

| 8 | 18.0-22.0 | |||

| 10 | 10.0-14.0 | |||

| 12 | 8.0-11.0 | |||

| 14 | 6.0-8.0 | |||

| 16 | 5.0-7.0 | |||

| 18 | 4.0-5.0 | |||

| 20 | 3.0-4.0 | |||

| 25 | 2.5-3.0 | |||

| 30 | 2.0-2.5 | |||

| tambaga | 3 | 20.0-25.0 | 40000 | O₂ |

| 4 | 18.0-20.0 | |||

| 5 | 15.0-18.0 | |||

| 6 | 10.0-15.0 | |||

| 8 | 6.0-10.0 | |||

| 10 | 2.0-3.5 | |||

| 12 | 2.0-2.5 | |||

| 14 | 1.5-2.0 | |||

| 16 | 1.0-1.5 | |||

| 20 | 0.6-1.0 |

Pondokna, serat laser bisa motong ngaliwatan logam sakumaha ipis 1mm sarta sakumaha kandel salaku 100mm atawa leuwih, dina laju sakumaha slow salaku 0.05m/ mnt jeung gancang salaku 100m/ mnt atawa leuwih, kalawan kakuatan laser mimitian ti 1000W ka 60000W. kakuatan béda jeung gas gawé bakal ngahasilkeun rupa ketebalan motong sarta speed.

Hal Anu Kedah Diémutan

Serat mesin motong laser anu cukup kuat pikeun motong bahan logam populér kalayan betah tur precision, malah sababaraha logam kacida reflective kayaning aluminium, tambaga, jeung kuningan. Tapi, éta rada nyusahkeun pikeun motong logam mulia sapertos emas sareng pérak. Ieu peryogi milarian pilihan kakuatan anu pangsaéna sareng gas anu tiasa dianggo, sareng nyaluyukeun pikeun nyetél anu leres motong laser parameter pikeun meunangkeun pakasaban rengse lancar tur ngahindarkeun runtah teu perlu.

Upami anjeun hoyong nganggo emas sareng pérak pikeun motong ornamén anu endah, perhiasan, karajinan sareng kado ogé sababaraha bagian sareng asesoris anu presisi, mangga naroskeun. STYLECNCStaf téknis pikeun kéngingkeun solusi pikeun bisnis sareng anggaran anjeun.